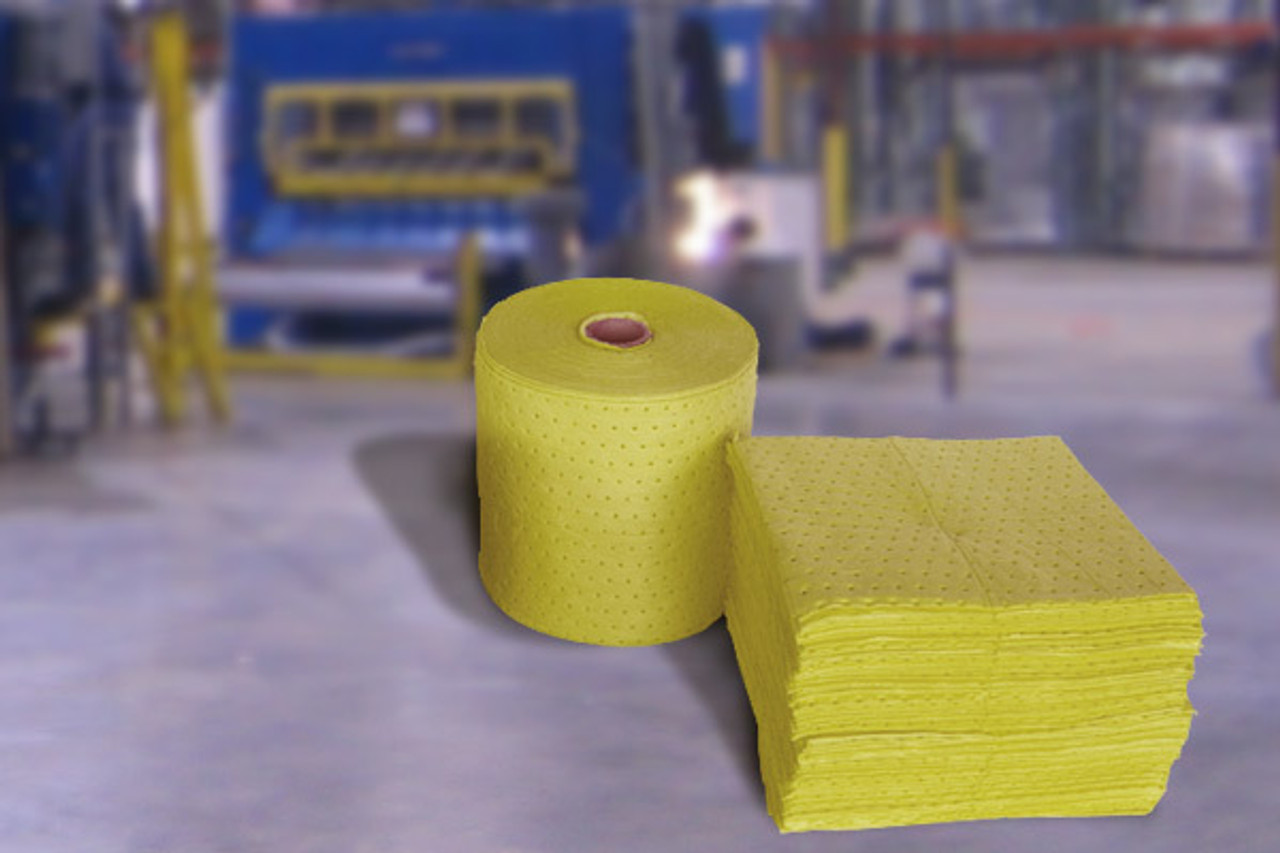

Oil Pads for Machines

Oil Pads for Machines: The Unsung Heroes of Machine Maintenance

Machines are the heart of any factory or workshop. They work hard, day in and day out, keeping production running smoothly. But with all that heavy lifting comes one inevitability—oil leaks. Whether it’s from moving parts, excess lubrication, or the occasional spill, oil and machinery tend to go hand in hand. And while a bit of oil might seem harmless, left unchecked, it can lead to accidents, equipment damage, and costly downtime.

Enter oil pads—the quiet, hardworking sidekicks in the world of machine maintenance. These humble pads are essential for controlling oil spills, keeping machinery clean, and ensuring a safer, more efficient work environment. But why exactly are oil pads so important? And how can you choose the right one for your machines? Let’s break it down.

Why Oil Pads are Essential for Machine Maintenance

Oil pads do more than just soak up oil (though they do that really well). They’re your first line of defense against a range of potential issues:

- Preventing Slips and Falls

Oil spills aren’t just a nuisance—they can be a safety hazard. In an environment where heavy machinery is moving around, oil on the floor can lead to serious slip-and-fall accidents. Oil pads absorb the spill quickly, reducing the risk of accidents and keeping your workspaces safe. - Protecting Machinery and Surfaces

Oil pads are also crucial for protecting your machines and surfaces. Oil that’s allowed to spill and accumulate can damage machine components, floor coatings, and even cause rusting over time. By using oil pads, you prevent these issues and ensure your machinery runs smoothly. - Minimizing Waste

Properly using oil pads helps contain spills, making cleanup quicker and less wasteful. Instead of letting valuable oil seep into the environment or be lost to messy spills, oil pads help you reclaim it, saving you money and reducing environmental impact. - Reducing Downtime

If your machines aren’t properly maintained, that can result in downtime and expensive repairs. By using oil pads to keep spills in check and protect equipment, you reduce the likelihood of machine malfunctions that result from oil leaks. It’s a proactive approach to maintenance that saves both time and money.

Key Features of Good Oil Pads for Machines

Not all oil pads are created equal. When choosing the right oil pad for your machines, here are some key features to keep in mind:

- Absorbency

The primary job of any oil pad is to soak up oil, so you’ll want one with excellent absorbency. High-quality oil pads should be able to absorb large amounts of oil quickly and efficiently without breaking apart or leaving residue behind. Look for pads that offer a high absorbent capacity per square foot, especially in high-demand environments. - Durability

Machines and industrial environments are tough on materials, so your oil pads need to be just as tough. The best oil pads will hold up to regular use without tearing, breaking, or falling apart too quickly. Look for pads made with strong, non-woven materials that can withstand the weight of machinery and large oil spills. - Non-Slip Design

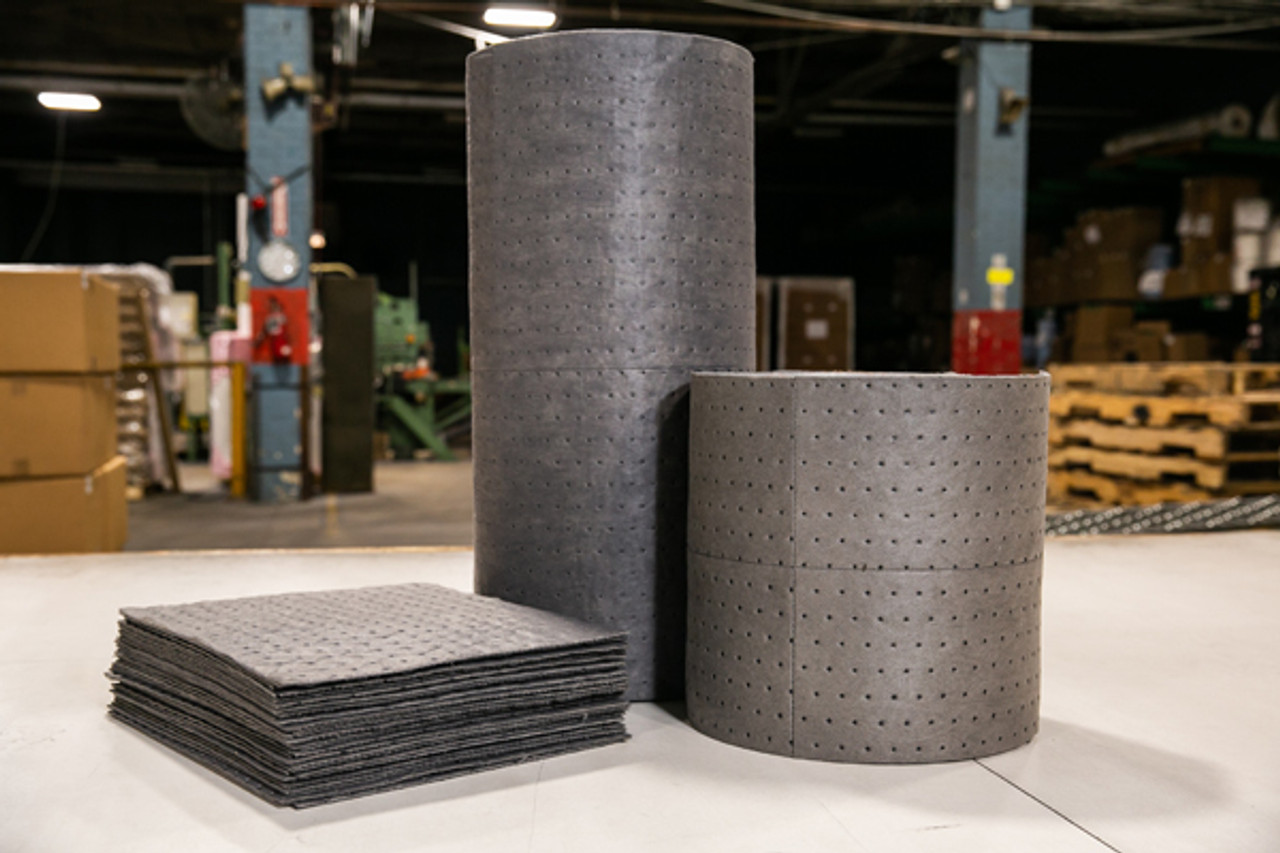

To prevent further accidents, many oil pads come with non-slip backing or are designed to stay in place even under pressure. When you’re working in an area with heavy machinery, this feature is a must-have for safety. - Size and Shape

Oil pads come in various sizes and shapes, so it's important to select the right one for your specific needs. Whether you’re placing them under machines, around parts, or on factory floors, having the correct size ensures maximum coverage and effectiveness.

Types of Oil Pads for Different Machine Needs

Different types of oil pads serve different needs. Here are the most common options:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

How to Use Oil Pads Effectively

To get the most out of your oil pads, you’ll need to use them strategically:

- Place Pads Where They’re Needed Most

Place oil pads under machinery, near oil filters, or around hydraulic components where leaks are most likely. Oil pads can also be used on factory floors or around equipment that’s prone to spills, so they’re always ready to absorb any oil drips. - Replace Pads Regularly

Keep an eye on your oil pads. Once they’ve absorbed a certain amount of fluid, they lose their effectiveness. Replace the pads regularly to ensure they’re doing their job efficiently. It's better to swap them out too soon than wait until they’ve absorbed too much and aren’t working as well. - Proper Disposal

Once the oil pads are saturated, they need to be disposed of properly. Many oil pads are disposable, but check local regulations for guidelines on disposal, especially if the oil contains hazardous materials. - Choose the Right Size for the Job

Don’t make the mistake of using a small pad for a large spill, or vice versa. Having the right-sized pad ensures the spill gets contained quickly, preventing it from spreading or soaking into the floor.

Conclusion: Keep Your Machines Clean, Safe, and Running Smoothly

Oil pads are an essential part of any machine maintenance routine. By helping to manage spills, reduce waste, and prevent safety hazards, oil pads can save you time, money, and a whole lot of stress. Plus, they’re an easy, low-cost way to keep your machines running efficiently and your workspaces safe and clean.

Ready to get your hands on some oil pads? Choose the right ones for your needs, and watch your machines—and your operations—run smoother than ever.